Surface Roughness Measurement In Metrology . surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. In this blog post, we explore everything you need to know from methods, to. There is a range of metrology technologies that are uniquely suited for different spatial frequencies. looking to get started with surface roughness measurement? metrology for measuring surface roughness. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. parameters of a surface with stratified functional properties. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan. These are referred to as ls or λs. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed.

from www.alamy.com

the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. metrology for measuring surface roughness. There is a range of metrology technologies that are uniquely suited for different spatial frequencies. looking to get started with surface roughness measurement? surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. These are referred to as ls or λs. In this blog post, we explore everything you need to know from methods, to. parameters of a surface with stratified functional properties.

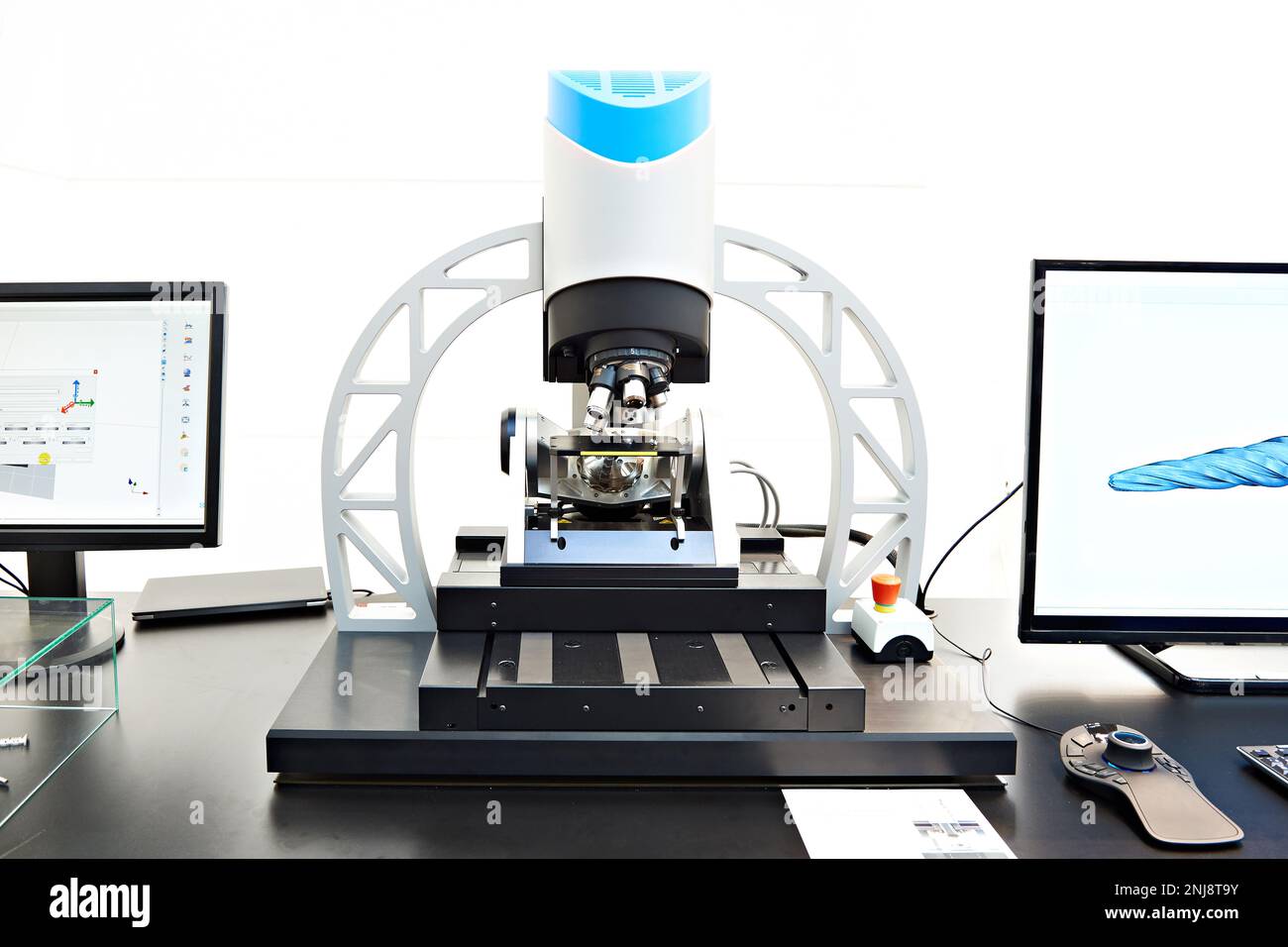

Optical 3D surface measurement system dimensional metrology and roughness measurement Stock

Surface Roughness Measurement In Metrology the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan. surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. looking to get started with surface roughness measurement? the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan. metrology for measuring surface roughness. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. There is a range of metrology technologies that are uniquely suited for different spatial frequencies. These are referred to as ls or λs. parameters of a surface with stratified functional properties. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. In this blog post, we explore everything you need to know from methods, to.

From www.researchgate.net

3D whitelight interferometry for surfaceroughness measurement. Download Scientific Diagram Surface Roughness Measurement In Metrology In this blog post, we explore everything you need to know from methods, to. There is a range of metrology technologies that are uniquely suited for different spatial frequencies. metrology for measuring surface roughness. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. parameters of a surface with stratified functional properties. . Surface Roughness Measurement In Metrology.

From mavink.com

Surface Roughness Units Surface Roughness Measurement In Metrology surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. parameters of a surface with stratified functional properties. looking to get started with surface roughness measurement? surface roughness measurement is. Surface Roughness Measurement In Metrology.

From mavink.com

Surface Roughness Standards Surface Roughness Measurement In Metrology the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan. metrology for measuring surface roughness. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. looking to get started with surface roughness measurement? surface roughness is quantified by. Surface Roughness Measurement In Metrology.

From www.youtube.com

Metrology and Instrumentation Surface roughness measurement Part 2 YouTube Surface Roughness Measurement In Metrology surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. These are referred to as ls or λs. In this blog post, we explore everything you need to know from methods, to. metrology for measuring surface roughness. looking to get started with surface roughness measurement? Rk, mr1, and mr2. Surface Roughness Measurement In Metrology.

From www.slideshare.net

Mechanical Measurement & Metrology Surface finish. PPT Surface Roughness Measurement In Metrology There is a range of metrology technologies that are uniquely suited for different spatial frequencies. parameters of a surface with stratified functional properties. metrology for measuring surface roughness. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. surface roughness is quantified by the deviations in the direction of the normal vector. Surface Roughness Measurement In Metrology.

From michmet.com

Nanometerscale roughness Michigan Metrology Surface Roughness Measurement In Metrology In this blog post, we explore everything you need to know from methods, to. parameters of a surface with stratified functional properties. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. metrology for measuring surface roughness. the measurement of surface roughness is a key quality control process. Surface Roughness Measurement In Metrology.

From www.edmdept.com

3D Metrology Surface Roughness Measurement & Tester Surface Roughness Measurement In Metrology surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. These are referred to as ls or λs. parameters of a surface with stratified functional properties. looking to get started with surface roughness measurement? surface roughness measurement is a value calculated by measuring the average. Surface Roughness Measurement In Metrology.

From www.metrology-services.com

Surface Roughness & Surface Finish Analysis Metrology Services from Dimensional Measurement Surface Roughness Measurement In Metrology surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. These are referred to as ls or λs. metrology for measuring surface roughness. In this blog post, we. Surface Roughness Measurement In Metrology.

From pdfslide.net

(PPTX) Surface finish measurement (mechanical measurement and metrology) Surface Roughness Measurement In Metrology In this blog post, we explore everything you need to know from methods, to. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan. surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. metrology for measuring. Surface Roughness Measurement In Metrology.

From www.alamy.com

Optical 3D surface measurement system dimensional metrology and roughness measurement Stock Surface Roughness Measurement In Metrology In this blog post, we explore everything you need to know from methods, to. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. These are referred to as ls or λs. There is a range of metrology technologies that are uniquely suited for different spatial frequencies. the measurement of. Surface Roughness Measurement In Metrology.

From www.slideshare.net

Surface finish measurement (mechanical measurement and metrology) Surface Roughness Measurement In Metrology parameters of a surface with stratified functional properties. In this blog post, we explore everything you need to know from methods, to. looking to get started with surface roughness measurement? These are referred to as ls or λs. metrology for measuring surface roughness. surface roughness is quantified by the deviations in the direction of the normal. Surface Roughness Measurement In Metrology.

From truegage.com

TrueGage Surface Metrology Software Surface Roughness Measurement In Metrology There is a range of metrology technologies that are uniquely suited for different spatial frequencies. metrology for measuring surface roughness. surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. the. Surface Roughness Measurement In Metrology.

From www.edmdept.com

3D Metrology & Surface Roughness Measurement EDMIS Surface Roughness Measurement In Metrology surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. metrology for measuring surface roughness. looking to get started with surface roughness measurement? These are referred to as ls or λs. the measurement of surface roughness is a key quality control process that can significantly. Surface Roughness Measurement In Metrology.

From www.youtube.com

Metrology of surface finish Measurement of surface roughness by stylus based equipment YouTube Surface Roughness Measurement In Metrology parameters of a surface with stratified functional properties. surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. Rk, mr1, and mr2 values are calculated from the linear. Surface Roughness Measurement In Metrology.

From michmet.com

Average Roughness basics Michigan Metrology Surface Roughness Measurement In Metrology Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan. surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its ideal. There is a. Surface Roughness Measurement In Metrology.

From www.mdpi.com

Micromachines Free FullText Estimation of Surface Roughness on Milled Surface Using Surface Roughness Measurement In Metrology looking to get started with surface roughness measurement? surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. parameters of a surface with stratified functional properties. There is a range of metrology technologies that are uniquely suited for different spatial frequencies. Rk, mr1, and mr2 values are calculated from. Surface Roughness Measurement In Metrology.

From www.slideserve.com

PPT A look at different surface roughness measurement methods with focus on 3D scanning Surface Roughness Measurement In Metrology parameters of a surface with stratified functional properties. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. looking to get started with surface roughness measurement? metrology for measuring surface roughness. surface roughness is quantified by the deviations in the direction of the normal vector of a real surface from its. Surface Roughness Measurement In Metrology.

From www.alamy.com

Optical 3D surface measurement system dimensional metrology and roughness measurement Stock Surface Roughness Measurement In Metrology These are referred to as ls or λs. Rk, mr1, and mr2 values are calculated from the linear curve (equivalent linear curve) minimizing. parameters of a surface with stratified functional properties. metrology for measuring surface roughness. surface roughness measurement is a value calculated by measuring the average of heights and depths across a processed. looking to. Surface Roughness Measurement In Metrology.